introduction

Machining is a widely used manufacturing process and one of the common processing methods in the manufacturing industry, used to manufacture various types of parts. Different types of parts require different processes to process to meet their specific requirements. Includes many different part types and machining processes. Here are some common machined part types and the machining processes commonly used for each type:

1.Shaft parts

Shaft parts are usually cylindrical and are used for connection and rotation. Common shaft parts include bearing shafts, rotating shafts, transmission shafts, etc. Machining processes include turning, grinding and threading. Turning, the most common method, involves rotating the workpiece and removing material with a tool to obtain the desired size and shape. For bearing shafts with high precision requirements, grinding can also be performed. In addition, shaft parts may require drilling, reaming, tapping and other processing processes.

2. Gear parts

Gear parts include various types of gears, such as cylindrical gears, bevel gears, etc., which are usually circular. The processing of gears usually includes milling, gear cutting, gear hobbing, gear shaping, gear shaving, grinding and heat treatment. Milling is used to create the basic shape of the gear, while gear cutting is used to cut the teeth of the gear. Grinding can be used to improve the accuracy and surface quality of gears. Heat treatment is often used to enhance the hardness and wear resistance of gears.

3. Bolts and nuts

Bolts and nuts are common elements used to connect parts. They are usually round or cylindrical and require turning, cutting and threading. Turning is used to create the main shape of bolts and nuts, while cutting is used to cut threads. Threading typically involves single-point thread cutting and thread rolling.

4. Plate parts

Plate parts include various types of flat plates, thin plates, metal plates, chassis, brackets, etc. Sheet metal parts are usually flat or curved. Processing techniques include surface grinding, milling, shearing, bending, stamping, welding and riveting. Shearing is used to cut the sheet into the desired shape, bending is used to bend the sheet, stamping is used to create holes and concave and convex or curved parts in the sheet, while welding and riveting are used to join different sheet parts together into a whole assembly .

5. Set of parts

Sets of parts usually include bearings, sliding bearings, flanges, etc. These parts usually require internal turning, internal grinding, cylindrical grinding and other machining processes to obtain accurate diameter and roundness. In addition, sleeve parts may require drilling, reaming, tapping and other processing techniques.

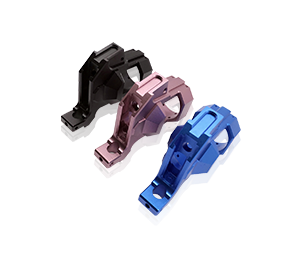

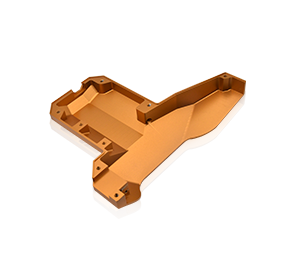

6. Block parts

Block parts include various types of squares, rectangular blocks, cylinders, etc. These parts often require surface grinding, milling and other machining processes to obtain precise flatness and contours. In addition, block parts may require drilling, tapping and other processing techniques

7. Casting parts

Cast parts are usually complex three-dimensional shapes, such as engine blocks, pump casings, etc. Machining processes include casting, grinding, turning and heat treatment. Casting is the primary method of making cast parts, where the shape of the part is created by pouring molten metal into a mold. Grinding, turning and heat treatment are then used to improve surface quality and accuracy.

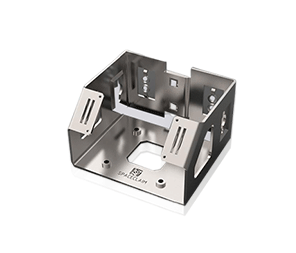

8. Box parts

Box parts include various types of machine casings, machine tool beds, etc. These parts usually need to be planarized

Machining processes such as grinding and milling to obtain precise flatness and contours. In addition, box parts may require drilling, tapping and other processing techniques.

9. Electronic parts

Electronic parts are usually small, such as circuit boards, connectors, etc. Processing techniques include cutting, stamping, welding and electroplating . Cutting and stamping are used to create shapes and holes for circuit boards, soldering is used to connect electronic components, and plating is used to protect and improve surface properties.

10. Plastic parts

Plastic parts are commonly used in various applications such as injection molding, extrusion molding, and compression molding. Injection molding makes parts by injecting molten plastic into a mold, extrusion molding squeezes the plastic into the desired shape, and compression molding heats the plastic and shapes it in a mold.

In addition to the above common types of machined parts, there are many other types of parts, such as special-shaped parts, free-form surface parts, etc. For each type of part, different machining processes can be used to achieve the required shape and size accuracy and surface quality. For example, for complex special-shaped parts, CNC machine tools can be used for multi-axis linkage processing; for free-form surface parts, three-coordinate measuring machines can be used for measurement and processing.

In summary, different types of parts require different machining processes to meet their specific requirements. Selecting the appropriate process and machining methods is critical to ensuring part quality, accuracy and performance. In actual manufacturing, the appropriate processing technology is usually selected based on the shape, material and requirements of the part to achieve the best processing effect.