introduction

The processing and customization of mechanical parts plays a vital role in modern industry. With the continuous development of industrial technology, the complexity, diversity, personalization and precision requirements of mechanical equipment are getting higher and higher. In this case, custom-made mechanical parts have become a key means to meet the needs of mechanical equipment. Choosing a suitable custom-made mechanical parts manufacturer can not only meet the company's processing needs, improve product quality and production efficiency, but also reduce production costs and enhance the company's market competitiveness. Therefore, for some parts with special needs, it is usually necessary to rely on professional custom-made mechanical parts manufacturers to meet the needs. This article will discuss how to choose a custom-made mechanical parts manufacturer that is suitable for you to ensure that your project goes smoothly;

How to choose a cnc machining manufacturer

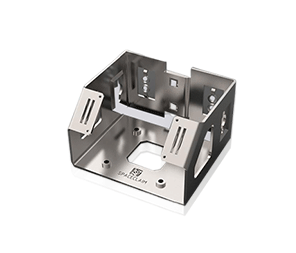

①Clear the processing requirements for customized parts

When choosing a custom-made mechanical parts manufacturer, you must first clarify the processing requirements of the parts. This includes the size, accuracy, materials, heat treatment, application environment and other requirements of the parts. Only with clear needs can we better screen manufacturers and ensure that the customized mechanical parts meet the actual needs of the enterprise. Different mechanical parts customization manufacturers may have different advantages, specialties and capabilities. Making sure you know your needs can help you find the most suitable partner.

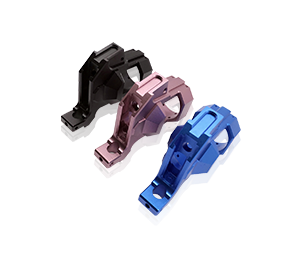

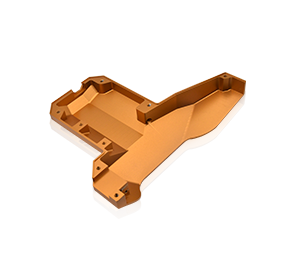

② Understand the processing advantages of custom parts factories

When considering a custom-made mechanical parts manufacturer, you should pay attention to the manufacturer's processing advantages. This includes the manufacturer’s equipment, technology, experience, etc. An excellent custom-made mechanical parts manufacturer should have advanced processing equipment and professional technical personnel, and be able to provide high-quality processing technology and an experienced production management team. These advantages will directly affect the quality and production efficiency of parts. For example, some manufacturers are good at CNC machining and are suitable for making parts with complex shapes. Some manufacturers may focus on precision parts customization and focus on the manufacturing of high-precision parts. Understanding a manufacturer's processing technology and equipment can help you determine whether it is suitable for your needs.

③Verify the processing experience of the custom parts factory

When choosing a custom-made mechanical parts manufacturer, it is also very important to understand their experience and professionalism. Check out their past projects and customer reviews to see if you have experience with similar projects. It is often more secure to cooperate with manufacturers who have successfully completed similar projects before, because they have accumulated relevant experience and knowledge, which can avoid many mistakes or unexpected events.

④Ensure the production capacity of custom parts factories

When choosing a custom-made mechanical parts manufacturer, you need to understand its production capacity and production cycle. An excellent custom-made mechanical parts manufacturer should have sufficient production capacity to meet the company's order needs and be able to adjust production plans according to customer needs. At the same time, manufacturers should be able to provide accurate production cycle forecasts to ensure that companies can reasonably arrange production plans and improve overall production efficiency. Especially when large quantities are required, it is necessary and wise to choose a manufacturer with high production capacity.

⑤Compare quotations from custom parts factories

When choosing a custom-made mechanical parts manufacturer, quotation is also an important factor to consider. Different manufacturers may adopt different quotation strategies, so detailed price comparisons must be made when choosing. It should also be noted that not only the price itself, but quality is always the primary guarantee. At the same time, you should also consider whether the manufacturer's quotation includes other costs, such as logistics, taxes, etc. Comprehensive comparison of quotations from different manufacturers can better control the company's costs and ensure that there are no hidden fees.

⑥After-sales service

Last but not least, consider the after-sales service of the mechanical parts customization manufacturer. If problems arise during production or even during use or need to be modified, repaired, redone, etc., good after-sales service can help you solve the problem and ensure that the project proceeds as planned.

Summarize

To sum up, choosing a custom-made mechanical parts manufacturer requires comprehensive consideration of many factors. First, we need to clarify the processing requirements of the parts, and then understand the manufacturer's processing advantages, experience, matching, production capacity, quotation and after-sales service. When screening manufacturers, pay attention to choosing manufacturers with advanced equipment and technology, rich experience and good after-sales service. Comprehensive consideration of these factors can help companies find the most suitable custom-made mechanical parts manufacturers, thereby providing strong support for the company's production and development.