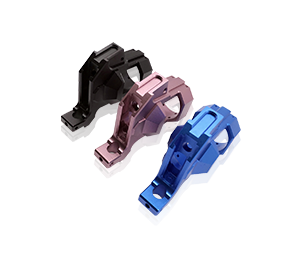

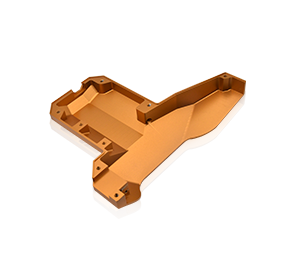

1. Aluminum Alloys

Aluminum alloys offer excellent strength-to-weight ratios, high thermal and electrical conductivity, and natural protection against corrosion. They are easy to machine and have low volume costs, so they are often the most economical choice for manufacturing custom metal parts and prototypes.

Aluminum alloys are typically less strong and harder than steel, but they can be anodized to create a hard protective layer on their surface.

Aluminum 606 is the most common and versatile aluminum alloy, offering a good strength-to-weight ratio and excellent machinability.

Aluminum 608 has similar compositional and material properties to 6061. It is more commonly used in Europe because it meets British Standards.

Aluminum 7075 is the most commonly used alloy in aerospace applications where weight reduction is critical because it has excellent fatigue properties and can be heat-treated to high strength and hardness comparable to steel.

Aluminum 5083 has higher strength than most other aluminum alloys and excellent seawater resistance, so it is commonly used in construction and marine applications. It is also an excellent choice for welding.

Material Properties:

l Typical density of aluminum alloy: 2.65-2.80 g/cm3

l Can be anodized

l Non-magnetic

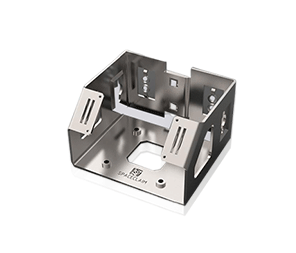

2. Stainless steel

Stainless steel alloys have high strength, high ductility, excellent wear and corrosion resistance, and are easily welded, machined and polished. Depending on their, they can be (essentially) non-magnetic or magnetic.

Stainless steel 304 is the most common stainless steel alloy and has excellent mechanical properties and good machinability. It is resistant to most environmental conditions and corrosive media.

Stainless steel 316 is another common stainless steel alloy with mechanical properties similar to 304. Although it has higher corrosion and chemical resistance, especially to salt solutions (e.g. seawater), it is often preferred for applications in harsh environments.

Stainless Steel 2205 Duplex is the strongest stainless steel alloy (twice as strong as other common stainless steel alloys) and has excellent corrosion resistance. It is used in harsh environments and has many applications in the oil and gas industry.

Compared to 304, stainless steel 303 has excellent toughness but lower corrosion resistance. Due to its excellent machinability, it is often used in high volume applications such as the manufacture of nuts and bolts for aerospace applications.

Stainless steel 17-4 (SAE grade 630) has mechanical properties comparable to 304. It can be precipitation hardened to a very high degree (comparable to tool steel) and has excellent chemical resistance, making it suitable for very high-performance applications such as the manufacture of turbine blades.

Material properties:

l Typical density: 7.7-8.0 g/cm3

l Non-magnetic stainless steel alloys: 304, 316, 303

l Magnetic stainless steel alloys: 2205 Duplex, 17-4

3. Low carbon steels

Mild steels have good mechanical properties, good machinability and good weldability. Due to their low cost, they can be used for general purpose applications including the manufacture of machine parts, jigs and fixtures. However, mild steels are susceptible to chemical corrosion and attack.

Mild steel 1018 is a general purpose alloy with good machinability and weldability as well as excellent toughness, strength and hardness. It is the most commonly used mild steel alloy.

Mild Steel 1045 is a medium carbon steel with good weldability, good machinability, high strength and impact resistance.

Mild Steel A36 is a common structural steel with good weldability. It is suitable for a variety of industrial and construction applications.

Material properties:

l Typical density: 7.8-7.9 g/cm3

l Magnetic

4. Alloy steels

Alloy steels contain other alloying elements in addition to carbon, resulting in increased hardness, toughness, fatigue and wear resistance. Similar to mild steel, alloy steel is susceptible to corrosion and chemicals.

Alloy steel 4140 has good overall mechanical properties with good strength and toughness. The alloy is suitable for many industrial applications but is not recommended for welding.

Alloy Steel 4340 can be heat treated for high strength and hardness while maintaining its good toughness, wear resistance and fatigue strength. This alloy is weldable.

Material properties:

l Typical density: 7.8-7.9 g/cm3

l Magnetic

5. Tool steels

Tool steels are metal alloys with very high hardness, stiffness, wear resistance and heat resistance. They are used in the manufacture of manufacturing tools (hence the name) such as molds, stamps and dies. In order to obtain good mechanical properties, they must be heat-treated.

Tool steel D2 is a wear-resistant alloy that retains its hardness at temperatures up to 425°C. It is used in the manufacture of tools and molds. It is commonly used in the manufacture of cutting tools and molds.

Tool steel A2 is an air-hardening general purpose tool steel with good toughness and excellent dimensional stability at high temperatures. It is commonly used in the manufacture of injection molds.

Tool Steel O1 is an oil-hardening alloy with a hardness of up to 65 HRC. it is commonly used for knives and cutting tools.

Material properties:

Typical density: 7.8 g/cm3

Typical hardness: 45-65 HRC

6. Brass

Brass is a metal alloy with good machinability and excellent electrical conductivity, making it ideal for applications requiring low friction. It is also commonly used in architecture to create components with a golden appearance for aesthetic purposes.

Brass C36000 is a material with high tensile strength and natural corrosion resistance. It is one of the easiest materials to work with, so it is often used in high volume applications.

Material properties:

Typical density: 8.4-8.7 g/cm3

Non-magnetic