The medical device industry encompasses a vast product line ranging from artificial joints to diagnostic equipment to therapeutic devices. Even so, there are often overlapping needs in different applications, which can help narrow down material choices. For example, most devices require surfaces that do not absorb moisture and can be easily sterilized.

Medical device components are typically manufactured through injection molding, 3D printing, and CNC machining, which offers the benefits of high customization, tight tolerances, good surface finishes, and certified material selection. When CNC machining is used, parts are typically milled using three to five axes or turned using a movable tool CNC lathe. Below are the top metal and plastic materials for machining medical device products.

Medical Device Plastics and Composites

The most common plastics used for medical devices have low water absorption (moisture resistance) and good thermal properties. Most of the materials listed below can be sterilized using autoclave, gamma or EtO (Ethylene Oxide) methods. Low surface friction and better temperature resistance are also preferred by the medical industry. In addition to direct or indirect contact with housings, fixtures, and guides, plastics can be used as an alternative to metal, where magnetic or RF signals may interfere with diagnostic results.

| Material Name | Material Properties |

| Polyformaldehyde (Acetal) | The resin has good moisture resistance, high abrasion resistance and low friction. |

| Polycarbonate (PC) | Polycarbonate has almost twice the tensile strength of ABS and offers excellent mechanical and structural properties. Widely used in automotive, aerospace, medical and other applications requiring durability and stability. Solid filled parts can be fully dense. |

| PEEK | Resistant to chemicals, abrasion and moisture, PEEK has excellent tensile strength and is often used as a lightweight alternative to metal parts in high-temperature, high-stress applications. |

| Ultra High Molecular Weight Polyethylene | Ultra-high molecular weight polyethylene is a versatile material. It offers unique abrasion and corrosion resistance, low surface friction, high impact strength, high chemical resistance and does not absorb moisture. |

| Teflon (PTFE) | Teflon's chemical resistance and performance at extreme temperatures exceeds that of most plastics. It is resistant to most solvents and is an excellent electrical insulator. |

| Polypropylene (PP) | PP has excellent electrical properties with little or no moisture absorption. It can carry light loads for long periods of time at widely varying temperatures. It can be machined into parts that require chemical or corrosion resistance. |

| Garolite G-10 | Garolite G-10 is made of epoxy resin reinforced with fiberglass cloth, also known as epoxy grade industrial laminate and phenolic resin. This material offers high strength and low moisture absorption. CNC machined Garolite is often used as an alternative to metal parts when structural features cannot be magnetic. |

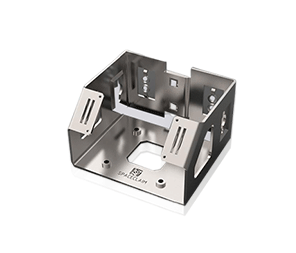

Metals for Medical Devices

The best machinable metals for the medical device industry have inherent corrosion resistance, sterilizability and are easy to clean. Stainless steels are very common because they do not rust, have low or no magnetic properties, and are machinable. Certain grades of stainless steel can be further heat treated to increase hardness. Materials such as titanium have a high strength-to-weight ratio, which is beneficial for handheld, wearable and implantable medical devices.

| Material Name | Material Properties |

| Stainless steel 316/L | Stainless steel 316/L is a highly corrosion-resistant steel widely used in medical devices. |

| Stainless steel 304 | Stainless steel 304 has a good balance of corrosion resistance and workability, making it one of the most widely used stainless steel alloys, but it cannot be hardened for heat treatment. If hardening is required, 18-8 stainless steel is recommended. |

| Stainless steel 15-5 | Stainless Steel 15-5 has similar corrosion resistance to Stainless Steel 304 with improved workability, hardness and high corrosion resistance. |

| Stainless steel 17-4 | Stainless steel 17-4 is a high-strength, corrosion-resistant stainless steel alloy that is easy to heat treat. This material is commonly used in medical equipment. |

| Titanium grade 2 | Titanium Grade 2 is a high strength, low weight and high thermal conductivity metal. It is a high purity unalloyed material. |

| Titanium grade 5 | The excellent strength-to-weight ratio and high aluminum content in Ti-6Al-4V increase its strength. This is the most commonly used form of titanium and has good corrosion resistance, weldability and formability. |

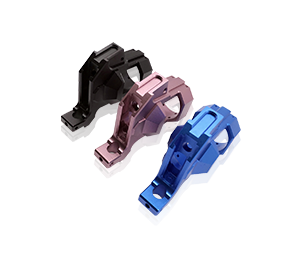

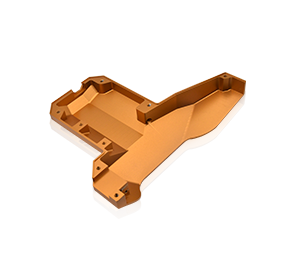

CNC Machined Medical Parts

Whether a medical or dental project requires machined titanium or smooth PTFE, manufacturing platforms like Xometry provide immediate pricing, lead times, and allow for customized certifications and inspections in a single interface. xometry takes the guesswork out of choosing the best material with its knowledgeable engineers and extensive design resources for manufacturability. The platform also helps you choose the best machine shop by pairing jobs ordered through its AI-driven quoting platform with the best manufacturing partner for the project.

Whether a medical or dental project requires machined titanium or smooth PTFE, SHOWY can give you a quote with lead times, and with experienced engineers and extensive design for manufacturability resources, SHOWY can advise you on choosing the best material.