Learn about 5 ways to apply specific manufacturing methods to aerospace applications, including user interface panels, assembly tools and fixtures, vibration test fixtures, aerostructures, and sensor housings.

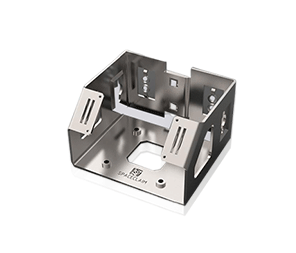

Application 1: Sheet Metal Buttons and User Interface Panels

Design tip: Sheet metal is a low-cost option for fabricating custom interface panels for integration into off-the-shelf components. Sheet metal-specific fasteners (such as PEM brackets and inserts) are an effective way to add threaded holes and tabs to thin sheet metal parts (as shown above).

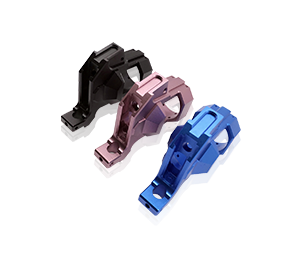

Application 2: Assembly Tools and Fixtures

Design Tip: Materials such as Aluminum 6061-T6 and Polyoxymethylene (POM) are often used in assembly tools due to their relatively low cost and ease of machining. Polyoxymethylene (POM) is also a good choice for preventing damage to interface components or when low friction is required.

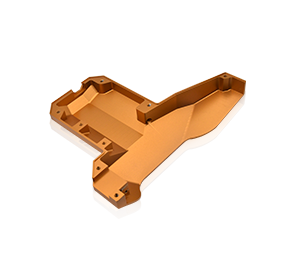

Application 3: Mass Simulation and Vibration Test Fixtures

Design Tip: Since flight is a non-static environment, electromechanical components and payloads are often subjected to high frequency vibration. The effects of this vibration are difficult to simulate, so physically accelerating life cycle testing on a shaker is often a critical step.

When designing fixtures, keep in mind that shakers often have strict weight limits to ensure safe operating parameters. The less mass the fixture occupies, the larger the test assembly will be.

Application 4: Machined Aerostructures and Airframe Components

Design Tip: Isogrid structures can be effective in reducing total weight while maintaining stiffness and ensuring uniform planar material properties. However, this strategy can significantly increase machine time, thereby reducing costs. Use isogrids only when weight reduction is critical and implement other strategies to facilitate fabrication, such as using the largest possible corner radii.

Application 5: Avionics and Sensor Housings

Design Tip: Machined housings are a great way to protect fragile sensors, such as commercial cameras, from harsh environments. To reduce weight, aluminum alloys are a common material used. Anodized coatings are an effective way to protect machined parts from corrosion while providing a harder, wear-resistant exterior surface.

Depending on the specific requirements, MIL-A-8625, Type 2 or Type 3 hard coat anodizing provides the most durable finish. However, anodizing reduces the fatigue strength of aluminum alloys, so be sure to carefully analyze parts subjected to cyclic loading.