introduction

CNC milling machine (Computer Numerical Control Milling Machine, CNC milling machine) is a high-precision, high-efficiency machine tool with many processing advantages. Below we will first understand the processing advantages of CNC milling machines, and then discuss in detail the different .

Processing advantages/features of CNC milling machines

High-precision machining: CNC milling machines can achieve very high machining accuracy and can meet the processing needs of parts with strict size and geometry requirements. This is critical for industries that require high precision, such as aerospace and medical device manufacturing.

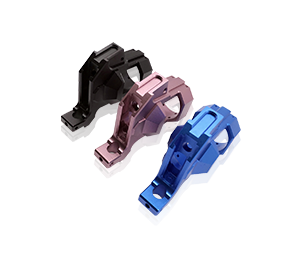

Complex shape processing

CNC milling machines can cut workpieces by moving the tool on three coordinate axes, so they are suitable for processing various complex shapes , including curves, concave and convex surfaces, porous structures, etc. This makes it an ideal processing equipment for manufacturing complex parts.

High production efficiency

CNC milling machines can greatly improve production efficiency through automated control. It can automatically execute programs, reducing operator operations and waiting time, thereby improving processing efficiency.

Mass production

CNC milling machines are suitable for mass production of similar parts because, once programmed, the same workpiece can be manufactured over and over again, ensuring consistency and accuracy.

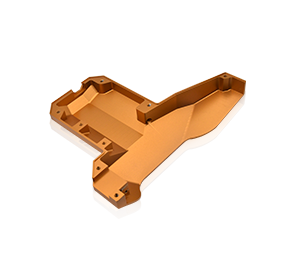

Various processing materials

CNC milling machines can process a variety of materials, including metals, plastics, ceramics and composites. The variety of processing materials makes it widely used in different industries.

Highly flexible

By changing the program, CNC milling machines can adapt to different processing needs and are also very suitable for customized production and small batch production.

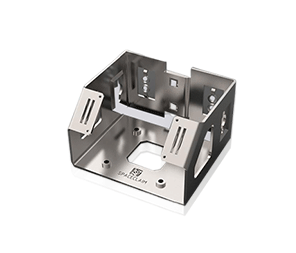

Automation and integration

CNC milling machines can be integrated with other automation systems, such as automatic clamping equipment, workpiece transfer systems and inspection devices , to further improve production efficiency and consistency.

Types of parts suitable for processing by CNC milling machines

Aerospace Components

The aerospace industry requires high-precision and complex parts, including engine components, flight controllers, and wing structures. CNC milling machines can meet these requirements while reducing human error.

Medical equipment

Medical device manufacturing requires highly precise components such as artificial joints, implants and surgical tools. CNC milling machines ensure the precision and quality of these parts.

car parts

CNC milling machines are used to manufacture automotive components, including engine parts, braking systems and steering components. They can be used for mass production as well as customized parts for specific car models.

Electronic equipment

Electronic equipment often requires precision parts such as heat sinks, circuit board brackets and chassis. CNC milling machines can cut these parts with precision .

Ships and shipbuilding industry

CNC milling machines can be used to manufacture hull components, ship engine parts, and ship equipment, ensuring their quality and reliability.

Tools and Dies

Making tools and molds requires a high-precision manufacturing process. CNC milling machines can produce molds for processes .

Engravings and Artwork

CNC milling machines can be used to create carvings, artwork, and intricate decorations because of their ability to cut a variety of materials with precision .

To summarize, CNC milling machines play a vital role in the manufacturing industry and are suitable for producing parts . Its high degree of automation and flexibility make it an ideal tool to meet the needs of different industries, increasing production efficiency, reducing costs and improving part quality.