introduction

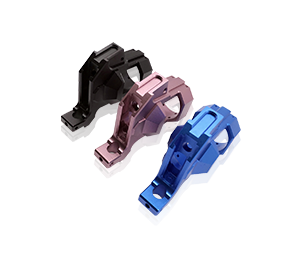

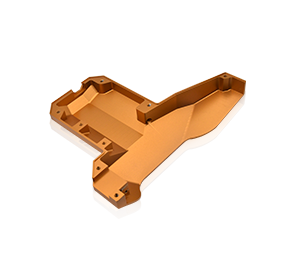

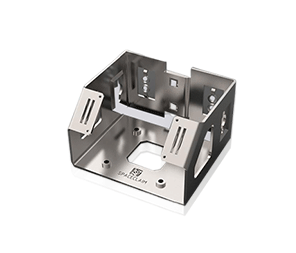

Metal parts processing is an important part of the manufacturing industry, and cleaning is one of the key steps in the metal parts processing process. The purpose of cleaning is to remove impurities such as dirt, oxides, excess grease and chips on the surface of parts to expose the pure surface of the metal, thereby improving the surface quality and performance of the parts. This article will introduce in detail the cleaning methods and precautions for metal parts processing.

metal parts Cleaning methods

1. Mechanical cleaning

Mechanical cleaning uses mechanical equipment and cleaning agents to remove dirt and impurities from metal surfaces. Commonly used mechanical cleaning methods include ultrasonic cleaning, drum cleaning and high-pressure water jet cleaning. These cleaning methods can effectively remove dirt and impurities from metal surfaces without causing damage to the metal surface.

2.Chemical cleaning

Chemical cleaning uses the action of chemical reagents to remove dirt and impurities from metal surfaces. Commonly used chemical cleaning agents include acids, alkalis, organic solvents, etc., which can chemically react with oxides, grease and other impurities on the metal surface to remove them.

3.Electrochemical cleaning

It uses electrolysis to remove dirt and impurities from metal surfaces. In the electrochemical cleaning process, by using the metal surface as a cathode or anode, electrolysis is used to generate gases such as hydrogen or oxygen, thereby blowing off or decomposing impurities on the metal surface.

4.Plasma cleaning

It uses the action of plasma to remove dirt and impurities from the metal surface. In the plasma cleaning process, high-energy ion beams are used to bombard the metal surface, so that surface dirt is impacted and detached, thereby achieving the purpose of cleaning the surface.

Main things to do when cleaning metal parts

1. Selection of cleaning agent: Choose a suitable cleaning agent according to the properties of the metal material and the type of surface dirt. Generally speaking, for metal materials with strong corrosion resistance such as stainless steel, you can choose pickling agents; for light metal materials such as aluminum and magnesium, you can choose alkali detergents; for organic impurities such as oil stains, you can choose organic solvents.

2. Cleaning temperature and time: Appropriate temperature and time can improve the cleaning effect. Generally speaking, the higher the temperature, the longer the cleaning time, and the better the cleaning effect. However, excessive temperature will cause oxidation of the metal surface and reduce the strength and corrosion resistance of the metal material. Therefore, the temperature and time should be reasonably controlled during the cleaning process.

3. Cleaning equipment: Choosing appropriate cleaning equipment can improve the cleaning effect and reduce the difficulty of operation. Commonly used cleaning equipment includes trough cleaning machines, spray cleaning machines, ultrasonic cleaning machines and high-pressure water jet cleaning machines. When using mechanical cleaning equipment, you should ensure that the performance of the equipment is stable, safe and reliable, and avoid problems such as surface damage or scratches on metal parts due to equipment failure or improper operation.

Summarize

Before using any cleaning method, the material, surface condition and required degree of cleaning of the metal parts should be evaluated, and appropriate cleaning methods and reagents should be selected. When using chemical cleaning agents, attention should be paid to selecting reagents with good chemical stability, low toxicity and environmental protection to avoid harm to operators and the environment. At the same time, attention should be paid to controlling operating parameters to avoid excessive damage or deformation to the surface of metal parts; at the same time, attention should be paid to environmental issues.