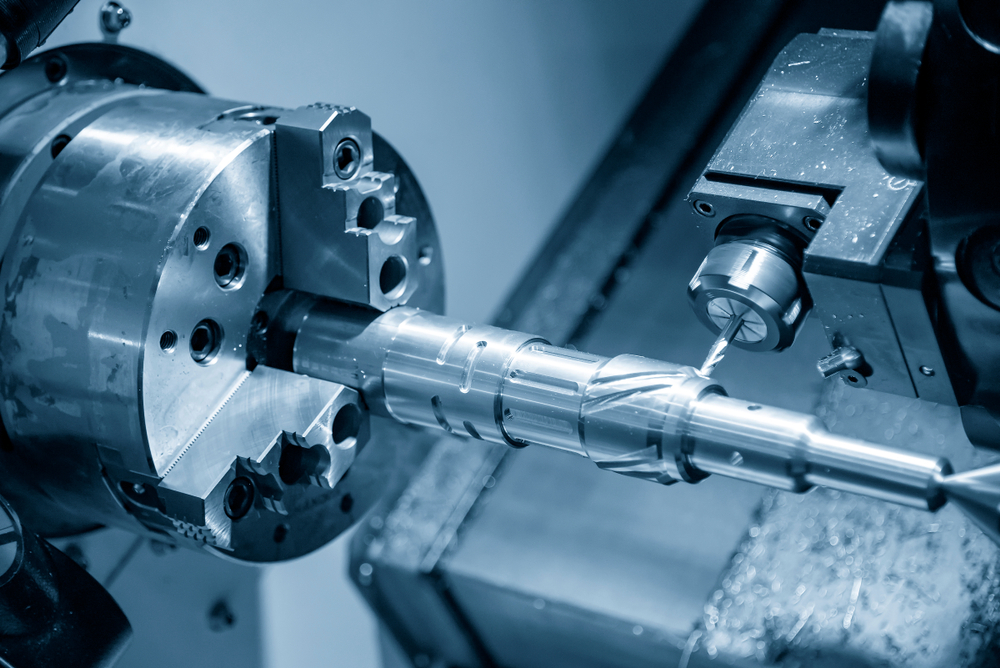

The main costs associated with CNC machining can be grouped into machining time, start-up costs, material costs, and feature costs. To reduce costs you need to understand the impact of these factors on cost.

The best way to reduce machining time is to design features that can be machined quickly, for example by choosing the correct radii for internal corners, reducing cavity depth, increasing wall thicknesses, limiting thread length and designing holes with standard sizes.

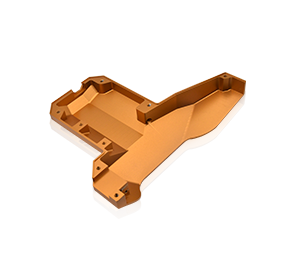

Material costs can be reduced by considering the size of the blank required, and the cost and machinability of the bulk material (softer alloys are faster to machine).

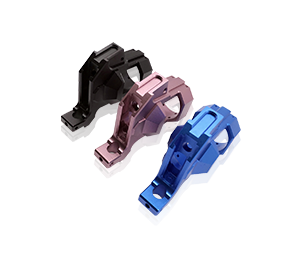

Start-up costs can be reduced by reducing the number part rotations or repositioning required to finish the part, for example by separating geometries into multiple parts that can be assembled later.

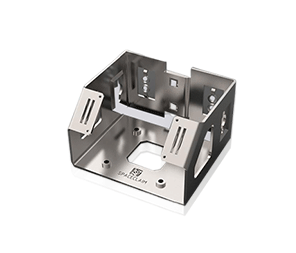

Feature costs can be reduced by only using tolerances when strictly necessary, removing all text & lettering, and avoiding multiple surface finishes.